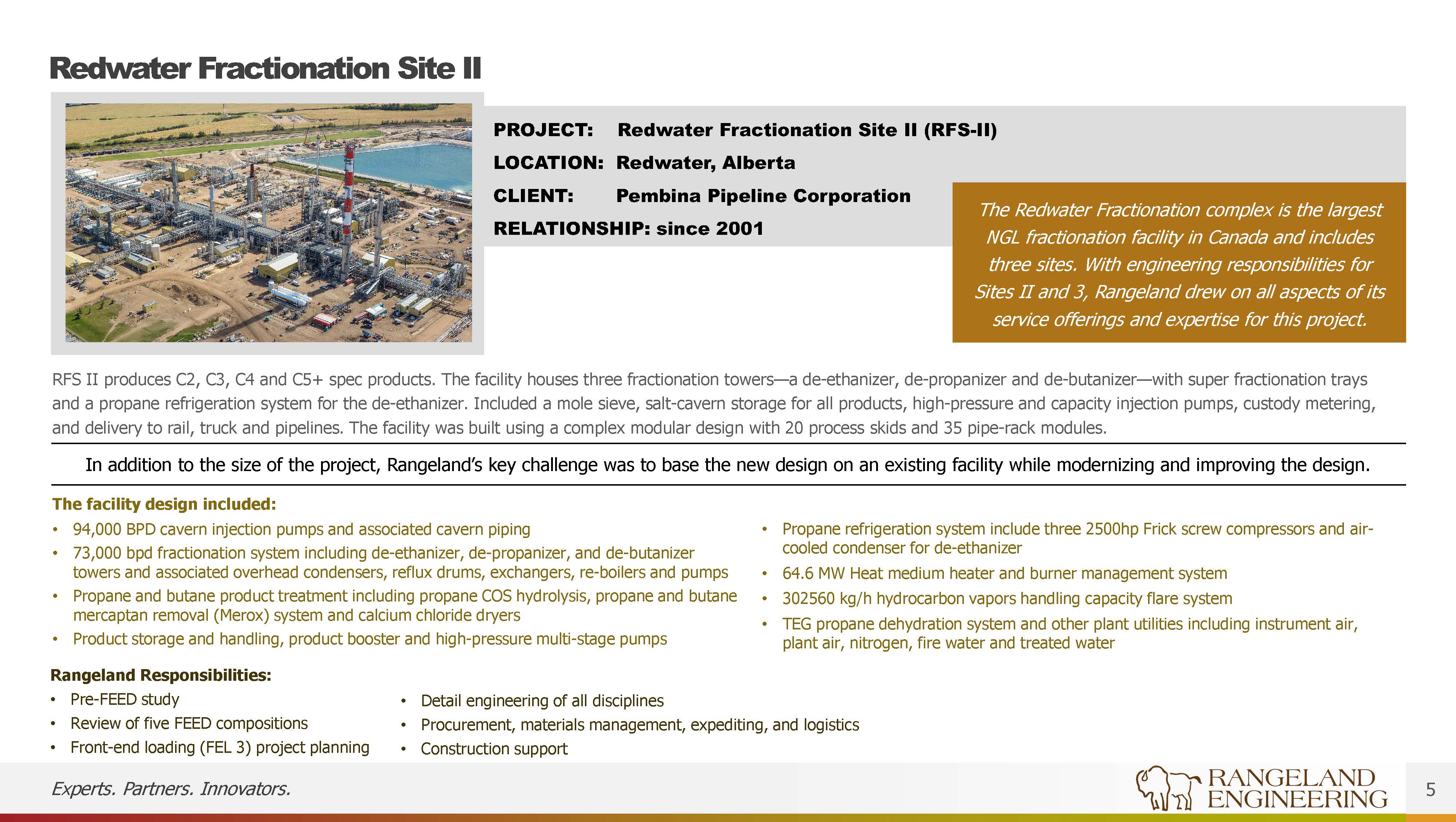

Redwater Fractionation Site II

RFS II produces C2, C3, C4 and C5+ spec products. The facility houses three fractionation towers—a de-ethanizer, de-propanizer and de-butanizer—with super fractionation trays and a propane refrigeration system for the de-ethanizer. Included a mole sieve, salt-cavern storage for all products, high-pressure and capacity injection pumps, custody metering, and delivery to rail, truck and pipelines. The facility was built using a complex modular design with 20 process skids and 35pipe-rack modules.

The facility design included:

•94,000 BPD cavern injection pumps and associated cavern piping

•73,000 bpd fractionation system including de-ethanizer, de-propanizer, and de-butanizer towers and associated overhead condensers, reflux drums, exchangers, re-boilers and pumps

•Propane and butane product treatment including propane COS hydrolysis, propane and butane mercaptan removal (Merox) system and calcium chloride dryers

•Product storage and handling, product booster and high-pressure multi-stage pumps

In addition to the size of the project, Rangeland’s key challenge was to base the new design on an existing facility while modernizing and improving the design.

Rangeland Responsibilities:

•

Pre-FEED study

•

Review of five FEED compositions

•

Front-end loading (FEL 3) project planning

•Detail engineering of all disciplines

•Procurement, materials management, expediting, and logistics

•Construction support

•Propane refrigeration system include three 2500hp Frick screw compressors and air-cooled condenser for de-ethanizer

•64.6 MW Heat medium heater and burner management system

•302560 kg/h hydrocarbon vapors handling capacity flare system

•TEG propane dehydration system and other plant utilities including instrument air, plant air, nitrogen, fire water and treated water

The Redwater Fractionation complex is the largest NGL fractionation facility in Canada and includes three sites. With engineering responsibilities for Sites II and 3, Rangeland drew on all aspects of its service offerings and expertise for this project.