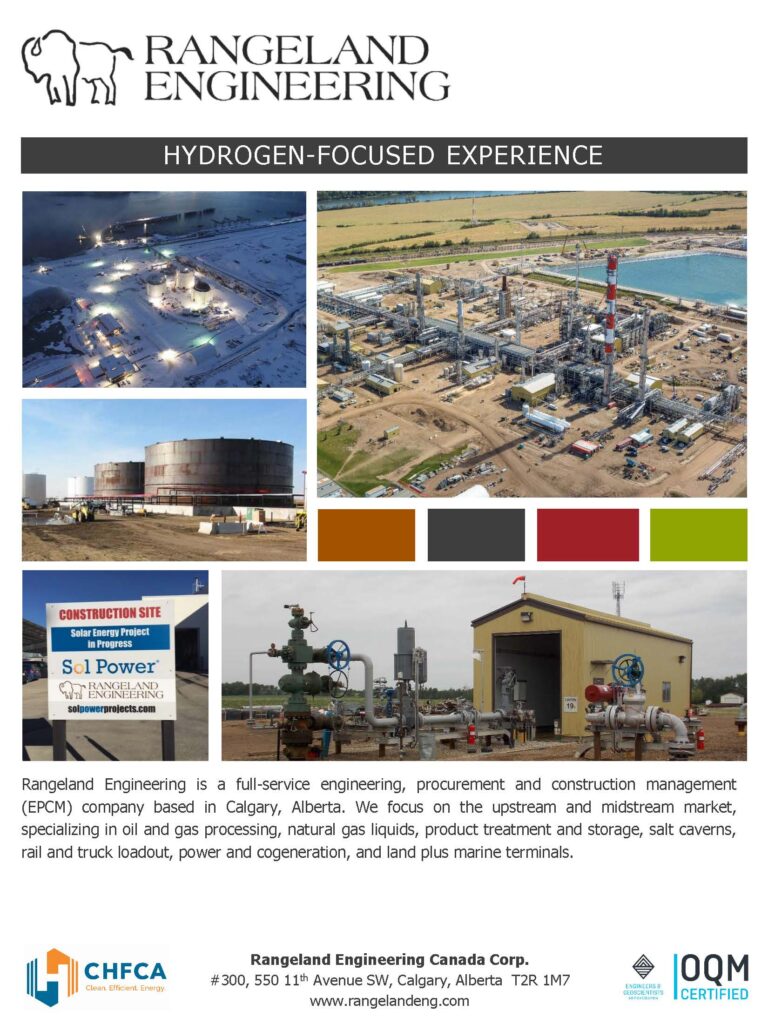

Hydrogen-Focused Experience

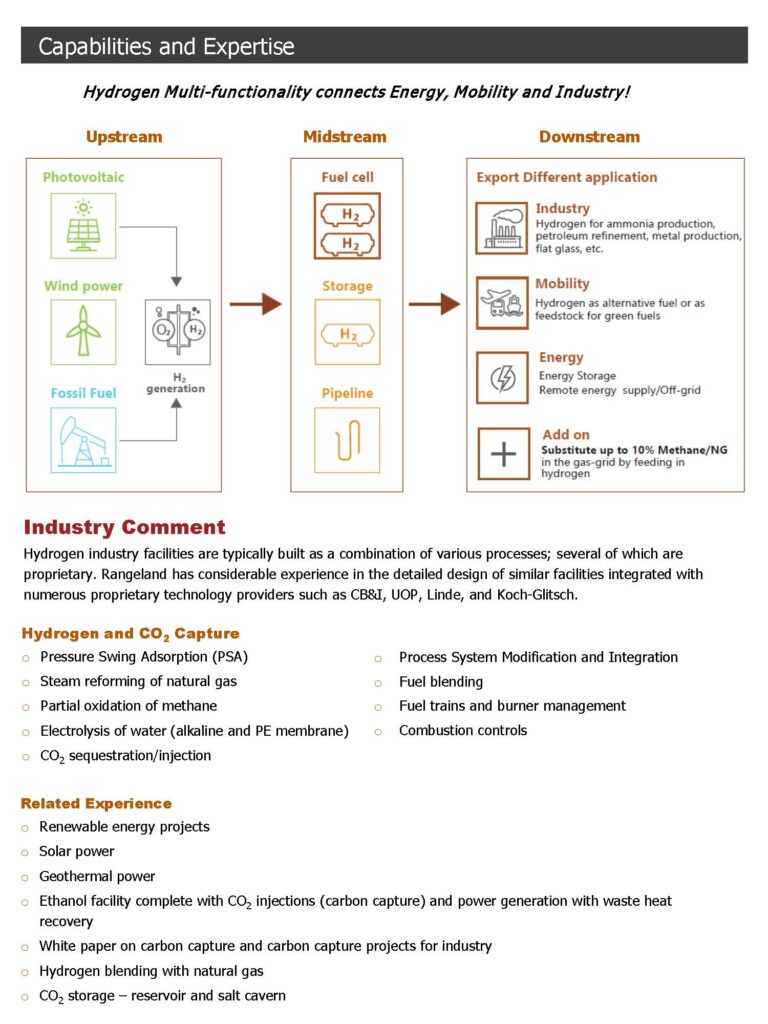

Industry Comment

Hydrogen industry facilities are typically built as a combination of various processes; several of which are proprietary. Rangeland has considerable experience in the detailed design of similar facilities integrated with numerous proprietary technology providers such as CB&I, UOP, Linde, and Koch-Glitsch.

Hydrogen and CO2 Capture

Pressure Swing Adsorption (PSA)

Steam reforming of natural gas

Partial oxidation of methane

Electrolysis of water (alkaline and PE membrane)

CO2sequestration/injection

Process System Modification and Integration

Fuel blending

Fuel trains and burner management

Combustion controls

Related Experience

Renewable energy projects

Solar power

Geothermal power

Ethanol facility complete with CO2injections (carbon capture) and power generation with waste heat recovery

White paper on carbon capture and carbon capture projects for industry

Hydrogen blending with natural gas

CO2storage –reservoir and salt cavern

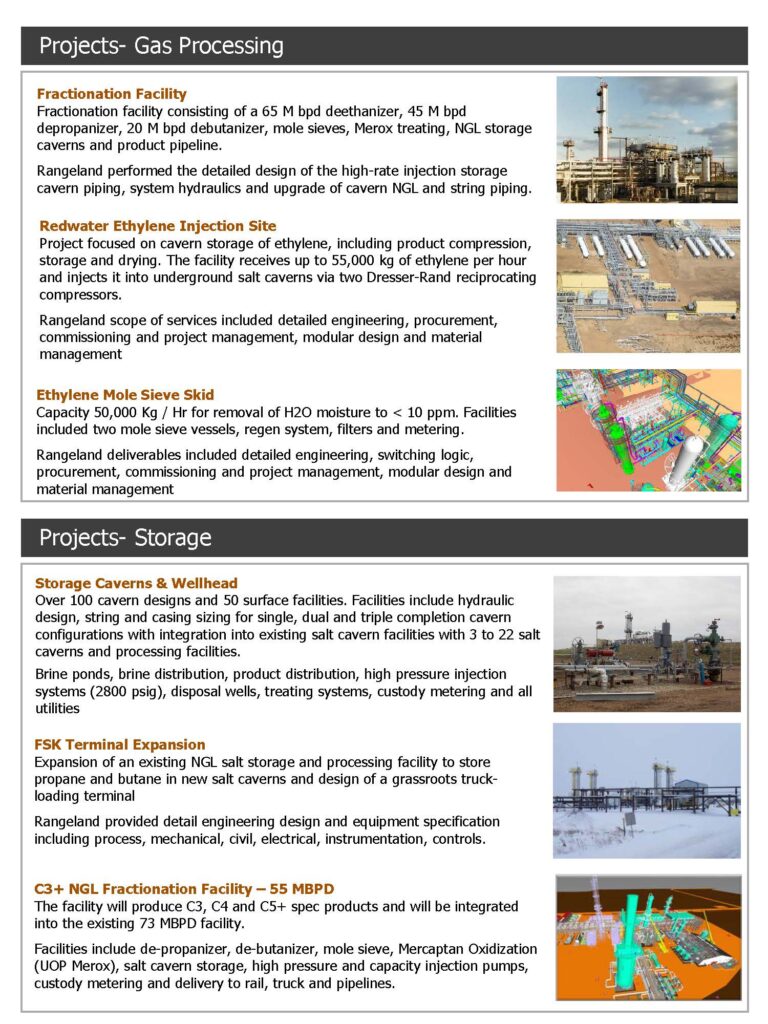

Fractionation Facility consisting of a 65 M bpd deethanizer, 45 M bpd depropanizer, 20 M bpd debutanizer, mole sieves, Merox treating, NGL storage caverns and product pipeline.

Rangeland performed the detailed design of the high-rate injection storage cavern piping, system hydraulics and upgrade of cavern NGL and string piping.

Redwater Ethylene Injection Site Project focused on cavern storage of ethylene, including product compression, storage and drying. The facility receives up to 55,000 kg of ethylene per hour and injects it into underground salt caverns via two Dresser-Rand reciprocating compressors.

Rangeland scope of services include detailed engineering, procurement, commissioning and project management, modular design and material management25px. Ethylene Mole Sieve Skid

Capacity 50,000 Kg / Hr for removal of H2O moisture to < 10 ppm. Facilities included two mole sieve vessels, regen system, filters and metering.

Rangeland deliverables included detailed engineering, switching logic, procurement, commissioning and project management, modular design and material management. Storage Caverns & Wellhead Over 100 cavern designs and 50 surface facilities. Facilities include hydraulic design, string and casing sizing for single, dual and triple completion cavern configurations with integration into existing salt cavern facilities with 3 to 22 salt caverns and processing facilities.

Brine ponds, brine distribution, product distribution, high pressure injection systems (2800 psig), disposal wells, treating systems, custody metering and all utilities

FSK Terminal Expansion of an existing NGL salt storage and processing facility to store propane and butane in new salt caverns and design of a grassroots truck-loading terminal

Rangeland provided detail engineering design and equipment specification including process, mechanical, civil, electrical, instrumentation, controls. C3+ NGL Fractionation Facility –55 MBPD The facility will produce C3, C4 and C5+ spec products and will be integrated into the existing 73 MBPD facility.

Facilities include de-propanizer, de-butanizer, mole sieve, Mercaptan Oxidization (UOP Merox), salt cavern storage, high pressure and capacity injection pumps, custody metering and delivery to rail, truck and pipelines.

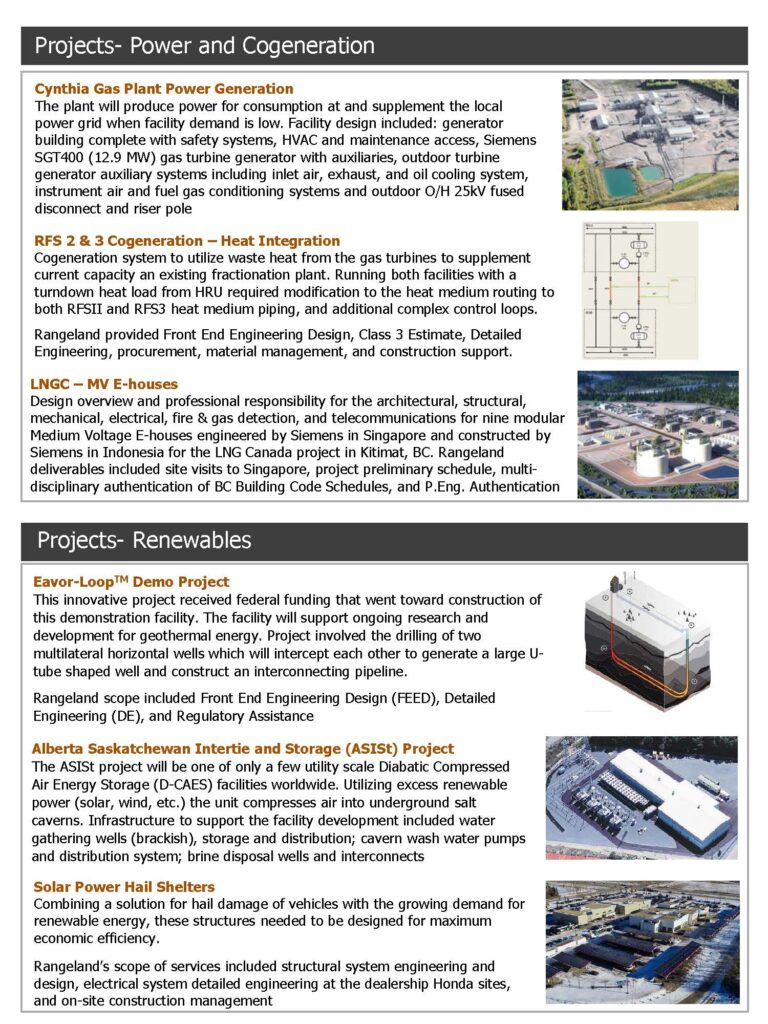

Cynthia Gas Plant Power Generation

The plant will produce power for consumption at and supplement the local

power grid when facility demand is low. Facility design included: generator

building complete with safety systems, HVAC and maintenance access, Siemens

SGT400 (12.9 MW) gas turbine generator with auxiliaries, outdoor turbine

generator auxiliary systems including inlet air, exhaust, and oil cooling system,

instrument air and fuel gas conditioning systems and outdoor O/H 25kV fused

disconnect and riser pole

RFS 2 & 3 Cogeneration – Heat Integration

Cogeneration system to utilize waste heat from the gas turbines to supplement

current capacity an existing fractionation plant. Running both facilities with a

turndown heat load from HRU required modification to the heat medium routing to

both RFSII and RFS3 heat medium piping, and additional complex control loops.

Rangeland provided Front End Engineering Design, Class 3 Estimate, Detailed

Engineering, procurement, material management, and construction support.

LNGC – MV E-houses

Design overview and professional responsibility for the architectural, structural,

mechanical, electrical, fire & gas detection, and telecommunications for nine modular

Medium Voltage E-houses engineered by Siemens in Singapore and constructed by

Siemens in Indonesia for the LNG Canada project in Kitimat, BC. Rangeland

deliverables included site visits to Singapore, project preliminary schedule, multidisciplinary

authentication of BC Building Code Schedules, and P.Eng. Authentication.

Eavor-LoopTM Demo Project

This innovative project received federal funding that went toward construction of

this demonstration facility. The facility will support ongoing research and

development for geothermal energy. Project involved the drilling of two

multilateral horizontal wells which will intercept each other to generate a large Utube

shaped well and construct an interconnecting pipeline.

Rangeland scope included Front End Engineering Design (FEED), Detailed

Engineering (DE), and Regulatory Assistance

Alberta Saskatchewan Intertie and Storage (ASISt) Project

The ASISt project will be one of only a few utility scale Diabatic Compressed

Air Energy Storage (D-CAES) facilities worldwide. Utilizing excess renewable

power (solar, wind, etc.) the unit compresses air into underground salt

caverns. Infrastructure to support the facility development included water

gathering wells (brackish), storage and distribution; cavern wash water pumps

and distribution system; brine disposal wells and interconnects

Solar Power Hail Shelters

Combining a solution for hail damage of vehicles with the growing demand for

renewable energy, these structures needed to be designed for maximum

economic efficiency.

Rangeland’s scope of services included structural system engineering and

design, electrical system detailed engineering at the dealership Honda sites, and on-site construction management.

As an EPCM firm, we have our own Health, Safety and Environment policies (HSE) policies and procedures, but we also integrate the HSE policies of our clients that we work with and follow their policies with strict adherence.

Our safety performance and commitment to our people continues to be outstanding; our TRIF = 0

Rangeland personnel that go to the site have mandatory WCB coverage and hold current safety training in First Aid, WHMIS and H2S Alive and will take any additional training that our clients require.

Rangeland maintains a QMS that focuses on ensuring all ofour engineering, design, procurement, and construction management activities produce deliverables that are safe, accurate, fit for purpose and constructible. Rangeland’s QMS undergoes continuous improvement and aligns with the requirements of ISO 9001:2015.

Our QMS has undergone audit by Engineers & Geoscientists of BC (EGBC) and has been awarded Organization Quality Management (OQM) certification, which affirms our compliance with the professional practice quality management standards of the engineering associations, in particular EGBC, APEGA and APEGS.

We are dedicated to developing relationships with Indigenous groups in creating sustainable business partnerships throughout Canada. Our philosophy includes:

A mandate to conduct business with Indigenous companies

Mutually beneficial partnerships to bring value to us as well as to Indigenous groups

Partnering with academic institutions and clients to develop a mentorship program for Indigenous students

Memberships with the Northeastern Alberta Aboriginal Business Association and the Canadian Council for Aboriginal Business

Gas Processing

Master planning, evaluation of gas monetization options, emissions reduction, and technical assessments for all treating options

Plant configuration surrounding hydrocarbon processing and contaminant removal

Functional gas processing requirements such as: local power generation, pipeline transfers, compressors, debottlenecking, pinch points and optimum methods of operation, including:

Gas Processing, Refrigeration, JT, Turbo Expander, Amine Treatment, Dehydration, Mole Sieve

Gas Compressor Stations

Pipelines and Facilities

Conceptual Design and Cost Estimating

Well Site Development and Pipeline Gathering Systems

Custody Transfer Metering, SCADA and Controls

Regulatory Applications

Construction Management

Storage and Facilities

Design specification and procurement of storage and offsite facilities:

Atmospheric Tanks

Refrigerated Tanks

Spheres

Bullets

Tube Storage

Blending Facilities

Product Pump Stations

Custody Metering

Cavern Storage

Product Loading/Unloading Facilities

Electrical

Instrumentation and Controls